FIXINGS AND FASTENERS

To complement our custom cutting we have machinery to aid your fixing and fastening needs.

The capacitor discharge process (stud welding system) is capable of welding various size threaded studs/stand-offs onto the back of stainless steel, aluminium, steel and brass. The advantage of using this method is that there is no visible marking on the face of materials 1.5mm or greater. Perfect for text, plaques, etc.

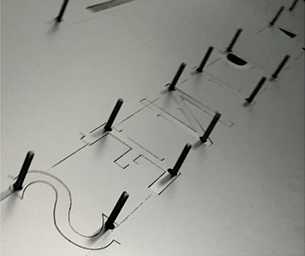

We can provide a stud location drill jig/template for easy installation.

Our insert machine allows for self clinching studs, nuts and other fasteners to be pressed into various materials for easy assembling components.

Looking for something custom to make your business stand out?

CD studs onto the back of stainless steel shown with drill jig for ease of installation.

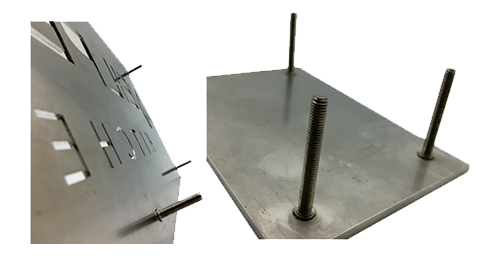

25mm CD stand-off studs onto the back of stainless steel lettering with laser coating. Corten Steel backing. CD standoff with female thread as per picture.

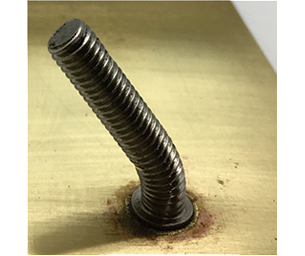

CD stud onto the back of brass, showing the shear strength of the weld.

Threaded stainless steel CD studs onto the

back of plates ready for fixing.

Nut inserts, pressed into

various materials for easy assembly.